|

General What do you understand by fiberwork materials | |||||||||||||||||

| A fiberwork material(FWM) comes into being by putting together several materials including a fiber material. In this case it´s high solid fibers in form of glass, carbon or aramid as well as a matrix in form of epoxy resin. | |||||||||||||||||

| |||||||||||||||||

| As a carpenter I already had substantial contact to a fiber material, so I knew a lot about dealing with anisotropic material. Moreover I´ve been reluctant to use metalic materials because of the arduous work on it for lack of proper machines, but I nevertheless wanted to build a fully faired bike without outside help. For lack of alternatives I acquired the necessary knowledge from literature and experiments without much bother. | |||||||||||||||||

| |||||||||||||||||

The good qualities in fiber direction are fully utilizable just in pure oneaxle use, e.g. tension bars, bending beams, etc. Most disadvantageous case of a construction ( regarding low weight ) is the quasi-isotropic laminate ( in all directions of the laminate plane the same material qualities by the arrangement of the fibers in many different directions ). The more UD ( unidirektional fabric with fibers only in one direction ) you use therefore, the bigger is the potential to low weight. | |||||||||||||||||

| |||||||||||||||||

|

In contrast to an isotropic material (e.g. alu) with the same qualities ( strength, E-module, etc.) in all directions, there´s a big difference in fiberwork materials in this regard. The fibers support just in fiber direction. But this is a disadvantage just if you fight against this quality instead of making use of it determined. | |||||||||||||||||

| |||||||||||||||||

|

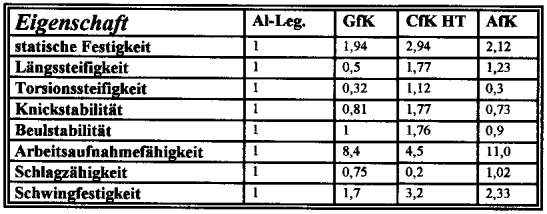

Here the comparison of qualities to aluminium :  There´s also the possibility to combinate several kinds of fiber in one laminate :

CF=carbonfiberplastic AF=aramidfiberplastic GF=glassfiberplastic I´d like to add to the kevlarfiber that its processing is much more difficult (e.g. with microgeared scissors). In addition kevlar gets unsightly under the influence of UV light and therefore it shouldn´t be used in the outer layer, also because in crashes or other injuries the surface gets rough resp."crumbly" and for that the repair is very difficult. | |||||||||||||||||

| |||||||||||||||||

|

In fabrics the threads cross right-angled (string and shot). The kind of crossing is called weaving and sets clearly the qualities of the fabrics.

| |||||||||||||||||

| |||||||||||||||||

|

The matrix has to hold the fibers in form and its contribution to stiffness is just marginal. The forces mainly get transmitted into the fibers. I´ve used the cold hardening system of resin L and hardener L from R&G in all parts, which has an even sufficient time to process of 40 minutes. Other systems are either too expensive, have a too short time to process or they need heat for hardening. | |||||||||||||||||

|

| |||||||||||||||||