|

| |

|

| |

|

A light and pressure resistant core material holds the distance between two thin layers. Because especially the outer layers take up the tension and pressure forces in the load case "bend", you can use lighter material for the core. Itīs responsible for the transfer of shear forces only. With the sandwich construction especially in combination with high strength fibers you can realize minimal weight with a big wall thickness.

| |

On which parts is this technique useful ? | |

|

On parts with a big area, so e.g. fairing parts, seats, etc. The flatter the form and the less edges and narrow radii, the easier is the production as sandwich. | |

selection of the core material | |

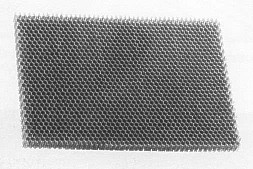

The with distance best shear and pressure strengths referring on weight has polyamid-honeycomb.

Itīs available e.g. at R&G in the thicknesses 1,5mm, 2mm, 3mm und 5mm. Iīve produced almost all parts with 2mm-honeycomb. Merely in exceptions (e.g. the seat) Iīve used 3mm or 5mm.

The with distance best shear and pressure strengths referring on weight has polyamid-honeycomb.

Itīs available e.g. at R&G in the thicknesses 1,5mm, 2mm, 3mm und 5mm. Iīve produced almost all parts with 2mm-honeycomb. Merely in exceptions (e.g. the seat) Iīve used 3mm or 5mm.Disadvantage of the honeycomb is the extreme high price. Alternatively with a little worse qualities you can use also balsa wood, polystyrene, thick cardboard or similar materials. | |

working steps | |

measurements to optimize the relation of thicknesses between outer layers and honeycomb core | |

|

target |

measurement |

|

increase of dent stiffness |

|

|

increase of strength |

|

|

increase of shock strength |

|

problems with sandwich parts | |

|

As soon as thereīs no adhesion any more between top and core layers it would come to extreme losses of stiffness and strength.

Those detachments can arise e.g. by knock loads.

| |

tips for vakuuming | |

|

| |

design of force introductions | |

|

| |