|

| |

|

| |

|

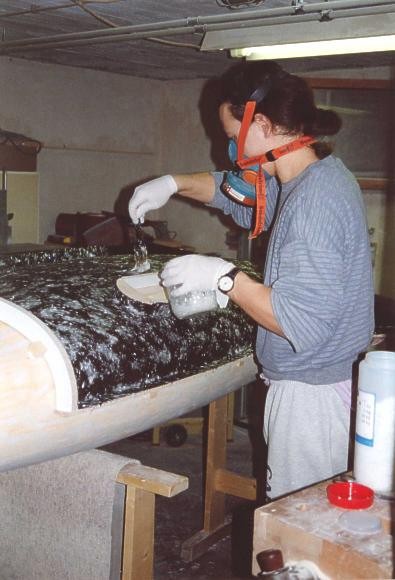

The production of the first form usually is the most timewasting working step. Especially polystyrene or wood are considered here as materials . The car industry frequently uses a special form mass, which gets put on a wooden framework. Iīve built the form for Magic Scooter 1 ( most of all owing to my experience with wood ) primarily with 20/5mm-strips, which I stretched and stuck over almost 20 crosswise chip boards. Before I put the boards onto two square steel bars and fixed them at an equal distance. Then the outer surface got sanded and filled, fixed against swell and dwindle with glass fiber, filled again and smoothed out. | |

|

| |

| Parts to be built only once can also get laminated directly over a light polystyrene core as e.g. at the frame of Magic Scooter 1. But by that you reach just a much worse surface which certainly can get improved by filling, but this means also more weight. This disadvantage has to be balanced with the advantage that you donīt need negative forms any more. | |

|

| |

|

For use in the negative form production especially with large parts the "Laminierkeramik" in combination with the glass fabric M1 from R&G is ideal, because you can realize stiff forms very quickly with it. Youīve to mix it with water and soak the mats then in it. Itīs untoxic and just one layer gives a thickness of 5mm. Even with very tall forms you donīt need more than 2 layers, which can in addition get reinforced with strips of the same material. Beforehand form resin has to get put on as top layer, after the first hardening followed by "elephant slop", a clutch layer consisting of resin, short glass fibers and cotton flocks. The soaked M1-mats then get laid on this clutch layer wet in wet. | |

|

| |